|

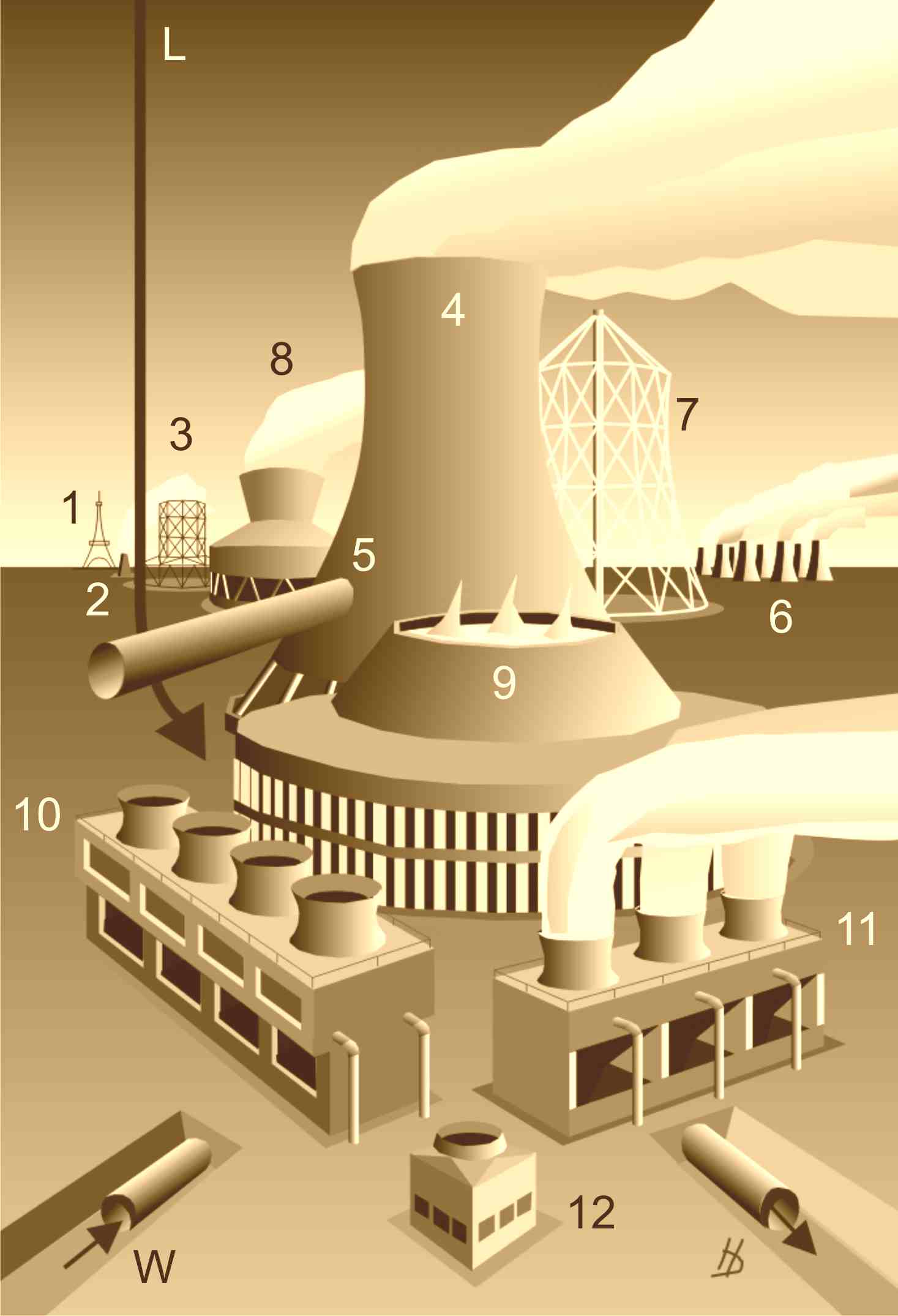

In cooling towers hot water (W) gets cooled by the ambient air (L) so establishing a cycle which saves water recources and prevents heating of rivers and lakes.

In “wet” cooling towers cooling water gets evaporated thus producing visible plume. “Dry” cooling towers do not have a visible plume as the cooling water is not in contact with the ambient air and water cannot evaporate. The so called “hybrid” cooling towers combine the wet and dry cooling process.

This tower (1) looks simply great! In the year 1889 G. Eiffel (1832-1923) completes the construction of this 300 Meter high tower, the design of which being based on a draft of M. Koechlin (1856-1946). In the year 1894 the first “natural draught cooling tower” is built, the chimney of which consisting of a 12 Meter high timber stack (2). With this invention Balcke for the first time uses the natural buoyancy for cooling the water in industrial processes and with this new product “Chimney Cooler” he establishes in the same year in the city of Bochum the Company BALCKE & Co., since 1972 Balcke-Dürr AG, today SPX Cooling Technologies GmbH.

From ther very beginning the demand for cooling water is growing strongly with the consequence of getting larger and larger cooling towers with higher and higher chimneys, these chimneys consisting of manifold types of cladded steel structures (3) in those times.

The first hyperbolic cooling tower with a chimney structure from reinforced concrete (4) is designed by the Netherlander F.K.Th. Van Iterson (1877-1957) and built by G. Kuypers as a general contractor in the war years 1917-1918 at a site of the Dutch State Mines in the city of Heerlen/NL. The tower height is 35 Meter and the shell wall thickness is 75 MM. Explaining the structural behavior of this chimney Van Iterson refers explicitly to Eiffel, who in a lecture explained the “form finding” of his tower.

This most convincing structural concept stimulates the fast and world wide spread of the hyperbolic reinforced concrete cooling tower, the chimneys of which targeting today the height of the Eiffel tower. Natural draught dry cooling towers with a circulating water flow of about 55000 m³/h e.g. have reached a height of 165 Meter above a base diameter of 163 Meter and with a throat diameter of 102 Meter.

Such heights together with the high capacity of heat to be discharged makes the cooling towers suitable for discharging flue gases together with the plume with the consequence, that a chimney stack no longer is required. For this purpose the cleaned flue gases are piped from the desulfurization plant into the cooling chiney at an adequate level using large diameter GRP-pipes (5). Also existing cooling towers can be converted for this duty and at the same time getting retrofitted as was done in the Jänschwalde power plant (6).

Double curved hyperbolic forms are a prerequisite for tensioned nets as they were used in an extraordinary manner for the roofs of the Munich Olympic stadium in the year 1972. A tensioned net was used for a cooling tower in the year 1974, the net cladded with aluminum sheets and tensioned by means of a 184 Meter high pylon. This 145 Meter high dry cooling tower for the nuclear power plant Schmehausen (7) was blown up in the year 1981 on the occasion of the shut down of this power plant.

The shells of cooling towers are extremely thin. So cooling towers with diameters of about 100 Meter and heights of about 200 Meter have wall thicknesses of about 250 MM. When smearing structural components of steel or cable net cooling towers together with the cladding the average thickness results in wall thicknesses of about 10 or 5 MM respectively.

An alternative concept for cooling towers is the forced or induced draught one having smaller sizes, shorter construction times, lower investment costs and a great flexibility. Induced draught round cooling towers with a circulating water flow of about 40 000 m³/h, a tower height of 50 Meter and a fan diameter of 26 Meter were a master stroke in apparatus and reinforced concrete construction (8).

An outstanding development is the forced draught round hybrid cooling tower. Characteristic for these towers are the two levels of air inlets for the wet and dry part with mostly sound attenuation panels in front of the fans. A very large installation of this type is the cooling tower for the Neckarwestheim nuclear power plant with a circulating water volume of 158000 m³/h; a height of 51 Meter and an outer diameter of 160 Meter. The inner wall with a diameter of 120 Meter has two levels of 44 fan openings each (9).

As from the beginning so today cell type cooling towers are built with timber, steel, concrete or fibre glass support structures. They have mostly induced draught fans on the roof deck and are designed as wet (11) or hybrid (10) cooling towers.

Smaller so called package cooling towers (12) are also products of cooling tower companies which are committed for more than 100 years to the cooling of water with innovative ideas for design and construction of cooling towers.

|